Contract document is a very important document that every personal

cannot afford to missed out. Failure to understand the content of this document

can lead to essential legal aspect of a contract which in the end will lead to

major financial losses. In view of this consequence, it is good to first

familiarised ourselves with the standard form of contract. The reason why this

is important mainly due to that all contract will be prepared base on standard

form of contract. Any extra requirement or specification normally will be added

in as special condition of contract.

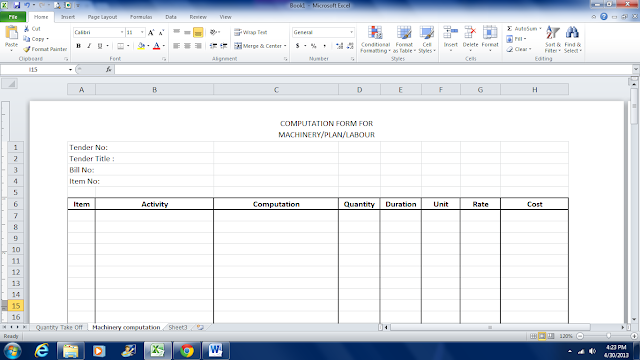

Base on my observation, most of the personal especially contractor,

always neglect this aspect during the tendering process. This missing stage in

tendering always resulted to contractor under price or under estimated the

actual construction cost. If only this practice had not been skip, there will

be lots of unnecessary losses to bare by parties involved. Under priced or

under estimated always happened with the lump sum contract where bill of quantity

is not provided in the tender document. Usually lump sum contract will only

mention on the major works that need to be completed. for example, there is

item describe as preliminaries and general, however it was not been elaborate

further. For instance, there is no detail item spell out in the bill of

quantity such as compliance to DOSH (Department of Occupational Safety and Health) act or environmental act or also compliance

to local statutory and regulatory. In actual fact all of this had been spelled

out in the standard form of contract.

As construction personal all of the standard form of contract

contents and also special condition of contract just cannot been separate from

the tendering process. For our further reference please refer to our respective

nation or department that we deal with for the standard form of contract. The

standard form of contract link that I include here might be useful to us.

STANDARD

FORM OF CONTRACT.